The phrase “what gets measured, gets managed” is everywhere, but it raises a better question: What exactly are we measuring? How do we decide which numbers matter most? How do we know if we are improving?

The phrase “what gets measured, gets managed” is everywhere, but it raises a better question: What exactly are we measuring? How do we decide which numbers matter most? How do we know if we are improving?

There is no single right answer. Every shop, project, and company has its own priorities. The real goal is consistency. Measure something, measure it the same way every time,and review it regularly. Over time, those consistent measurements become a mirror that reflects both progress and weakness.

Many shops track familiar metrics such as pounds per hour, weld inches, lineal feet, machine utilization or ratios of fittings to straights. These provide a snapshot of productivity and can be tracked across time. But they also have limits. Increasing coil line output might look like a win, but if that creates a bottleneck in assembly or shipping, what did you really improve? Metrics can highlight success, but they can also hide inefficiencies elsewhere in the system.

The danger lies in using isolated numbers as if they tell the whole story. Real insight comes from connecting each metric to the total workflow. When viewed together, performance patterns emerge. A spike in one area might explain a slowdown in another. That bigger picture is where true improvement happens.

Early in my construction technology career, I chased point solutions. Each one solved a narrow problem, such as spooling, tracking or reality capture. Each win felt like progress, but every fix revealed a new issue downstream. The problem was that those tools worked in isolation. Today, software platforms connect estimating, coordination, fabrication, logistics and installation. For the first time, we can see the whole system. That visibility means our measurements must evolve as well.

Systems thinking changes the question from “Are we improving this step?” to “Does this change improve the entire process?” Poorly chosen metrics can drive behavior that looks productive but hurts overall flow. When people chase metrics that do not align with company goals, they can optimize for local success rather than overall health.

Revenue is a good example. It is easy to compare and feel like growth, but it is not always meaningful. High revenue does not guarantee profit or stability. Chasing top-line growth through low-margin work can drain cash and morale. For fabrication-heavy firms, better indicators might include lower rework, higher field productivity driven by improved shop output, or a growing share of projects that leverage your prefabrication strengths.

Once the right metrics are in place, benchmarking gives them value. Tracking your own results over time shows progress and reveals backslides. Comparing to peers adds context. Peer groups are especially valuable because they collectively define metrics and openly share results, making comparisons fair and useful.

Benchmarking should not be about competition for its own sake. It should provide perspective. It shows whether your systems can scale, whether your profit margins are in line with peers, and where you can improve.

Metrics also drive alignment. What you choose to measure tells your teams what matters most. It connects daily work to company goals and helps people see how their efforts contribute to progress. When the wrong metrics are emphasized, they can confuse or demotivate teams, pulling them in opposite directions.

Metrics are a mirror. They reflect your priorities, your values, and your company’s health. Like training at the gym, progress takes time and consistent effort. The results appear slowly, but they build into something powerful.

So, ask yourself: Are you measuring what truly matters?

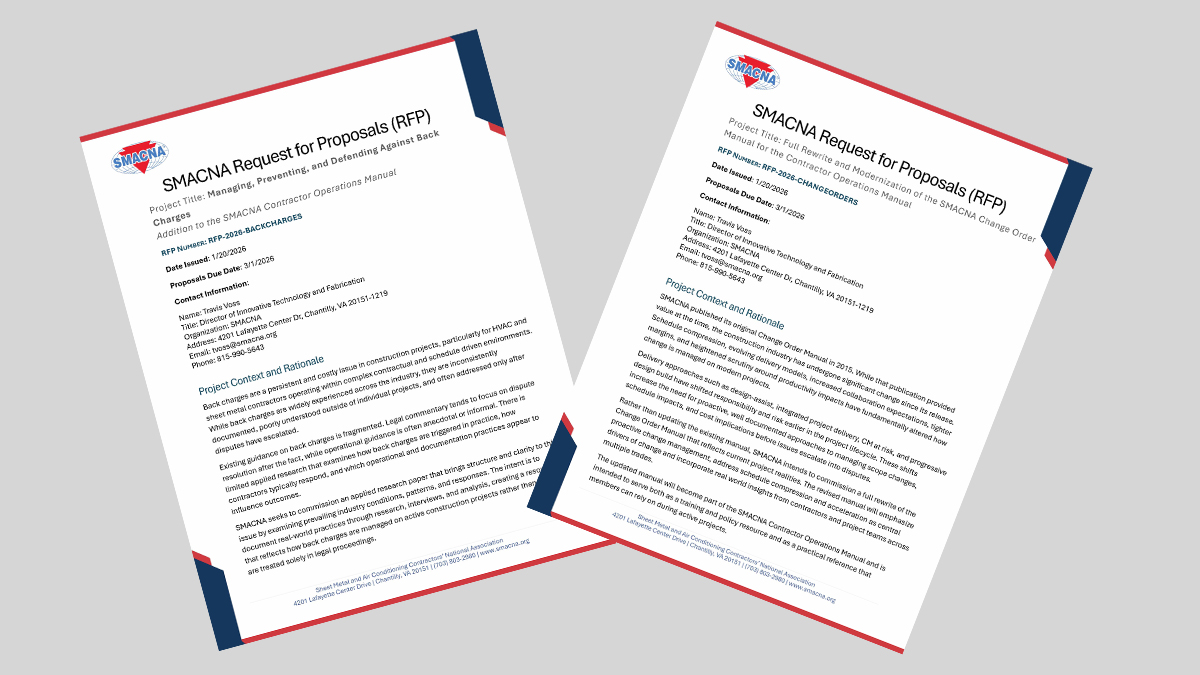

Travis Voss is the Director of Innovative Technology and Fabrication at SMACNA. He leverages his background in the tech field to explore, adapt and potentially develop technologies and workflows for the construction industry, particularly as it undergoes its digital transformation.